Aluminum 6061 vs 6063 are comparable in composition and mechanical characteristics. Aluminum 6061 and 6063 are both often used for extrusions. The most common types of aluminum include the 6000 series alloys, made with silicon and magnesium. The most widely used are 6061 and 6063, known as structural or architectural aluminum.

Specifically, 6061 aluminum is renowned for its durability and adaptability. Therefore, it is perfect for CNC machining and heavy-duty applications. On the other hand, because of its superior extrudability and smooth surface, 6063 aluminum alloy is preferred for architectural projects.

Engineers, manufacturers, and designers choose the best material for their projects by being aware of the distinctions between these two alloys. This article delves into the key properties, machinability, and applications of aluminum alloy 6061 T6 and 6063.

Aluminum 6061 vs 6063: Key Differences

The comparison of 6061 and 6063 aluminum is not simple due to the utilization of various tempers. Both naturally aged T4 and artificially aged T6 tempers are available for these alloys. The heat-treated, artificially aged versions are far more robust than their T4 counterparts.

Comparing the chemical makeup, mechanical characteristics, and common uses of aluminum 6061 and 6063 side by side might help you comprehend their differences. The following table provides a thorough summary of each alloy’s strengths, machinability, corrosion resistance, and applicability for different industrial and architectural tasks.

| Feature | Aluminum 6061 | Aluminum 6063 |

| Series | 6000 | 6000 |

| Main Alloying Elements | Magnesium (0.8–1.2%), Silicon (0.4–0.8%), Copper (0.15–0.4%) | Magnesium (0.45–0.9%), Silicon (0.2–0.6%) |

| Other Elements | Chromium, Iron, Zinc | Iron, Chromium, Zinc |

| Tensile Strength | 290–310 MPa | 170–210 MPa |

| Yield Strength | 240–270 MPa | 110–140 MPa |

| Elongation (%) | 12–17% | 8–12% |

| Hardness (Brinell) | 95 | 70 |

| Density | 2.70 g/cm³ | 2.70 g/cm³ |

| Corrosion Resistance | Good, slightly lower than 6063 | Excellent, better for outdoor exposure |

| Machinability | Excellent for CNC machining, easy to cut and drill | Good, but softer material can deform under heavy machining |

| Surface Finish | Moderate, can be anodized | Very smooth, ideal for architectural finishing and anodizing |

| Typical Applications | Aerospace components, automotive parts, marine structures, anchors | Window frames, door frames, railings, decorative trims, and architectural panels |

| Forming and Extrusion | Moderate, requires careful handling | Excellent, highly extrudable, and easy to bend/form |

| Heat Treatment | Can be T6 or T651 tempered for higher strength | Can be T5 or T6 tempered, mainly for improved surface finish |

The above table shows the main distinctions between Aluminum 6061 vs 6063 in terms of composition, mechanical characteristics, and uses. For aerospace, automotive, and marine components, 6061 aluminum is the best choice because of its exceptional strength, machinability, and capacity for heavy-duty applications.

On the other hand, 6063 aluminum is the material of choice for architectural projects like window frames, doors, railings, and ornamental trimmings because it is softer, more extrudable, and has a smooth surface finish. Engineers, designers, and manufacturers choose the best alloy depending on whether strength, machinability, or aesthetic finish is the main requirement, by being aware of these variations.

Mechanical Properties of Aluminum Alloy 6061 T6

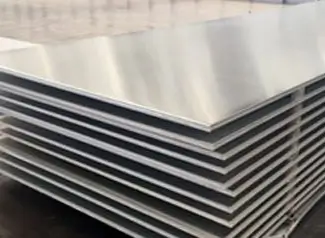

Aluminum alloy 6061-T6 is undoubtedly the more prevalent grade. It is distinguished by its ability to balance strength, corrosion resistance, and machinability. A three-step heat treatment procedure is used to get the “T6” temper:

Heat Processing: the aluminum alloy 6061 T6 is heated to a temperature of 530–560 °C for a set time. As a result, the alloying elements in the aluminum metal matrix create a uniform solution.

Pro: Creates a stable internal structure and gets the alloy ready for reinforcement.

Cons: Needs exact temperature control; the alloy can be harmed by excessive or uneven heating.

Aluminum Sheets Stack

Quenching: It is the process of rapidly cooling the heated solution to room temperature. By doing this, the solution’s homogeneous condition is “frozen,” preventing any particles from forming throughout the cool-down phase. Water is typically used as the quenching medium.

Pros: Preserves the supersaturated solid solution required for further hardening.

Cons: It can cause thin or complicated parts to break, deform, or experience residual pressures.

Aging: In this stage, the material is once more heated by the machine shop to a temperature of about 160–180 °C for 6–10 hours. Higher hardness and toughness are the results of the alloying elements precipitating in the aluminum matrix under extremely regulated and stable conditions. The material eventually returns to ambient temperature through a very slow cooling process.

Pros: Strengthens the alloy, Increases toughness, and hardness.

Cons: The material is prone to becoming brittle and losing strength due to over-aging or inadequate process control.

Typical Applications of Aluminum Alloy 6061 T6

The following are some commercial uses for 6061 T6 aluminum as an engineering material:

- Aerospace Parts

- Automobile components

- Fittings for marines

- Structural Frames

- Pipelines

- Strong extrusions

- Equipment for transportation

Colorful Aluminum Profiles

Aluminum 6063 T6 comes in flats, round and hexagon bars, hollow bars, square tubes, and channels, among other forms and sizes.

Understanding 6063 Aluminium Alloy

6063 aluminium alloy is referred to as an “architectural alloy due to its complex extrusion capabilities and mild strength. Aluminum alloys lose strength when exposed to high temperatures. However, they can retain their strength and even exhibit increased performance at low service temperatures.

Tempers and Properties of 6063 Aluminium Alloy

There are many tempers of 6063 alloy, each with a unique strength and formability:

- Annealed 6063-O: Low strength, great formability, and very soft.

- 6063-T1: Naturally aged and cooled from heat working; moderate strength.

- 6063-T5: Good hardness and medium strength; extrusion-cooled and artificially aged.

- 6063-T6: The strongest 6063 solution, heat-treated and artificially aged.

General Properties of 6063

- T6 Tensile Strength: about 190–240 MPa

- T6 Yield Strength: about 160–210 MPa

- Elongation: about 8–12%

- Length: about 8–12%

- Corrosion Resistance: Excellent resistance to corrosion, particularly when anodized.

- Workability: Excellent workability, particularly in extrusion.

- Surface Finish: Smooth, perfect for ornamental and anodizing applications.

6061 Aluminum Machinability and CNC Machining

Aluminum is shaped into high-quality parts and components using a variety of CNC machining techniques, such as milling, drilling, turning, and tapping.

Material 6061

Face Milling

Due to the 6061 aluminum machinability, a popular machining technique for creating flat surfaces is face milling. Using a high-speed face mill with carbide inserts and a high positive rake angle will yield the best results. To guarantee ideal cooling and lubrication and reduce tool wear, you should also use a coolant.

Drilling:

Another popular CNC machining technique used to create 6061 aluminum parts is drilling. Use high-speed steel or carbide drills with a sharp tip and a high helix angle for best results. Maintaining appropriate chip evacuation requires peck drilling, where the drill bit is regularly withdrawn to break up chips and keep them from clogging the flutes.

6061 Aluminum CNC Machining for Industrial Parts

Tapping:

A machining process called tapping is used to give 6061 aluminum components threaded holes. Use a high-speed steel or carbide tap with a sharp tip and a high helix angle for best results. Using a coolant is crucial to improving chip evacuation and lowering the heat produced during tapping. To enhance thread quality and lessen tap wear, tapping fluid or paste is also advised.

End Milling:

This machining process creates intricate profiles and forms on 6061 aluminum components. Using a high-speed end mill with carbide inserts and a high positive rake angle will yield the best results. A trochoidal milling method, which uses a circular tool path to increase chip evacuation and minimize cutting forces, is also advised.

Turning:

This type of machining creates cylindrical forms on 6061 aluminum components. Use a high-speed steel or carbide insert with a high positive rake angle and a sharp edge for best results. Using a coolant is crucial to improving chip evacuation and lowering the heat produced while turning. To reduce cutting forces and vibration, a light cutting depth and feed rate are also advised.

Aluminum Machining for Industrial Parts

Aluminum machining is a crucial step in advanced manufacturing. Aluminum machining is preferred for its portability, low weight, and resistance to corrosion. Aluminum is precisely formed into parts for the automotive, marine, aerospace, and general machinery sectors with the use of CNC machining.

The most often used grade of aluminum for industrial components is 6061. It is perfect for structural components because it provides a good mix of machinability, durability, and corrosion resistance. 6061 lowers the need for further post-processing since it machines cleanly, maintains tight tolerances, and produces smooth surface finishes.

Manufacturers can mill, turn, drill, and face aluminum with great accuracy and consistency thanks to CNC machining. This method ensures cost effectiveness and design flexibility for both prototypes and large-scale production runs.

Structural Applications of 6061 Aluminum

The excellent strength-to-weight ratio of 6061 aluminum makes it a reliable material for structural applications in a variety of sectors. It is perfect for challenging situations because of its exceptional machinability, corrosion resistance, and durability.

The following are typical structural applications for 6061 aluminum:

- Aerospace: Parts of the fuselage, aircraft wings, and fittings.

- Automotive: Suspension parts, vehicle chassis, and performance enhancements.

- Marine: Saltwater-resistant gear, masts, and boat frames.

- Building: load-bearing frames, pipelines, and bridges.

- Industrial equipment: Includes pressure tanks, bases, and supports for machinery.

Manufacturers can produce precision parts and custom forms that precisely match structural requirements since 6061 is a material that works well with CNC machining. Reliability is guaranteed in both lightweight and heavy-duty applications because of its strength and corrosion resistance balance.

Aluminum 6061 vs 6063: Which One Should You Choose?

The decision between aluminum 6061 and 6063 is based on performance requirements. 6061 aluminum is utilized extensively in structural, automotive, and aerospace applications because it is stronger and easier to machine. On the other hand, 6063 aluminum is favored for architectural and ornamental components like window frames, doors, and trims because it offers superior corrosion resistance and a nicer surface finish.

In summary, use 6061 aluminum if you want strength and longevity. 6063 aluminum is a superior choice if corrosion resistance and beauty are important considerations.

Conclusion

Aluminum 6061 and 6063 are both essential alloys in contemporary industry; their uses vary according to their characteristics. 6063 has a superior surface quality, making it perfect for architectural and decorative uses, whereas 6061 delivers more strength and is frequently utilized in structural and heavy-duty applications. Both alloys can be accurately molded into high-quality components using sophisticated CNC machining, and when combined, they provide the combination of machinability, durability, and performance required across a variety of sectors.