If you work in regulatory affairs or quality assurance, you already know how stressful an FDA audit can be. One inspector’s findings can disrupt operations, damage reputation, and even trigger enforcement actions. The real challenge? The rules evolve, and so do inspection priorities.

Deanna Bousalis, a former FDA investigator and now a respected consultant in the life sciences industry, offers a rare perspective. With years of experience on both sides of the inspection table, she knows what the FDA looks for, where most companies fall short, and what it takes to stay ahead.

Here are her insights on the most common findings, emerging patterns, and what your team can do to be better prepared.

Who Is Deanna Bousalis?

Deanna spent years inside the FDA inspecting pharmaceutical and medical device manufacturers, drafting Form 483s, and recommending enforcement actions when companies fell short. During her tenure, she developed a reputation for focusing not just on surface‑level documentation, but on whether systems worked as intended and risks were under control.

After transitioning to the private sector, she’s helped dozens of life sciences companies strengthen their compliance programs, build effective CAPAs, respond to FDA citations, and embed a culture of quality into their operations.

What sets her apart is her ability to bridge both perspectives — she knows what regulators expect to see, but also understands the operational pressures and resource constraints companies face when trying to get there.

Current FDA Audit Environment: What’s Changed

Since the COVID‑19 pandemic, FDA inspections have fully ramped back up, even surpassing pre‑2020 levels in some sectors. But the approach has evolved.

According to Deanna:

“We’re seeing inspectors take a more risk‑based approach, drilling deeper where they see trends or red flags. They expect you to know your risks — and to have them under control.”

Some of the biggest shifts she notes:

- Data integrity remains a central focus and one of the top reasons for warning letters.

- Greater attention to global supply‑chain transparency, with questions about how you qualify and monitor overseas suppliers.

- More rigorous scrutiny of environmental monitoring, especially in sterile operations.

- Expanded oversight of third‑party contractors and service providers, ensuring that outsourced activities don’t compromise quality.

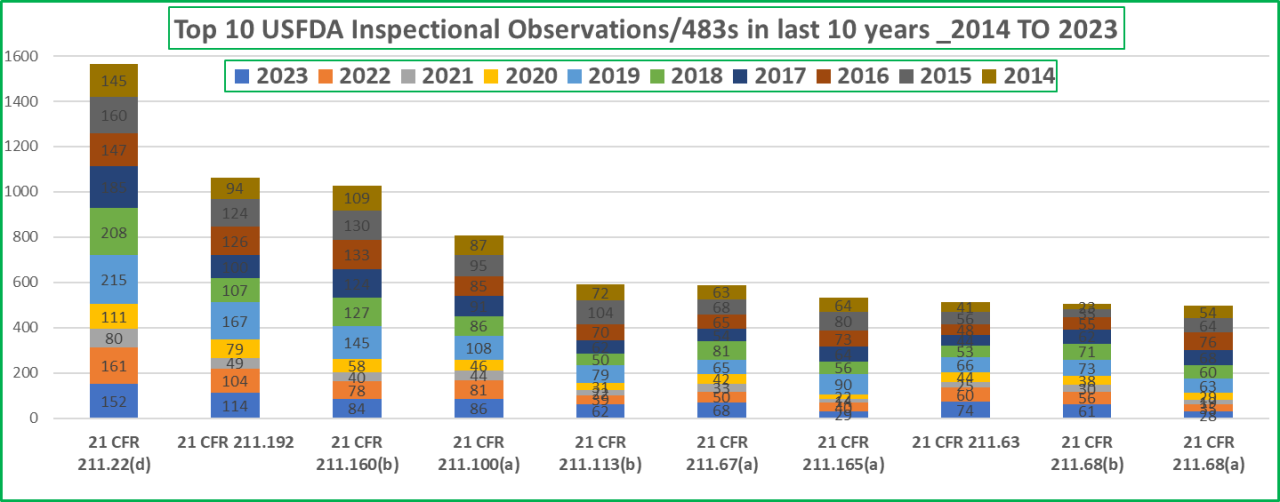

Last year alone, the FDA issued over 4,000 Form 483s, and the language in warning letters shows a growing emphasis on systemic failures rather than isolated mistakes. This trend underscores the agency’s push for companies to move beyond compliance “on paper” and demonstrate control in practice.

Top 5 FDA Audit Findings & Patterns You Can’t Ignore

Deanna has observed a few recurring weak spots, some obvious, some less so, that keep showing up in audits. Here are the five most common:

Data Integrity Weaknesses

Even after years of enforcement, many companies still fall short on ensuring their records are complete, accurate, and tamper‑proof.

- Missing metadata in electronic records

- Overwritten or missing audit trails

- Uncontrolled spreadsheets in QC labs

- Shared user logins or weak access control policies

How to fix it:

Strengthen your data governance and use tools like Atlas Compliance to monitor trends in data findings across the industry and benchmark against your peers.

Inadequate Supplier & Vendor Controls

Many companies overlook the fact that FDA expectations extend beyond their own walls. Missing qualification records, outdated supplier audits, and poorly documented monitoring of critical suppliers remain common.

How to fix it:

- Keep supplier qualification files current and risk‑based.

- Schedule and document routine supplier audits.

- Require clear CAPAs from suppliers when deviations or deficiencies occur.

- Prioritize critical suppliers in your risk assessments to focus resources where they matter most.

Poor CAPA Implementation

CAPA systems often fail not because companies ignore problems, but because they address only the symptoms. Inspectors continue to cite superficial investigations and ineffective follow‑up actions.

How to fix it:

- Conduct root‑cause analysis that goes beyond the obvious.

- Document the rationale for all chosen corrective and preventive actions.

- Assign clear ownership and timelines.

- Include effectiveness checks and follow-up to confirm resolution.

- Platforms like Atlas Compliance’s Copilot can even guide your team step by step through drafting thorough, regulator‑ready CAPAs.

Environmental Monitoring Gaps

In sterile and aseptic manufacturing, environmental monitoring remains a weak spot — and a priority for inspectors.

- Improper classification of cleanrooms

- Lack of trending on microbial and particulate counts

- Uninvestigated excursions or failure to adjust controls when trends shift

How to fix it:

- Review and validate your monitoring plan regularly.

- Establish meaningful alert and action levels based on historical data and regulatory expectations.

- Build trending into your routine reports and investigate trends early, before they escalate.

- Train operators on proper aseptic technique and documentation.

Lack of Inspector Profiling Awareness

One issue Deanna sees more and more: companies failing to research the inspector coming to their site. Inspectors have individual focus areas based on their background and prior assignments. If you don’t understand what your inspector tends to emphasize, you’re more likely to be caught off guard.

How to fix it:

- Review your facility’s prior inspection histories and closure letters.

- Use Atlas Compliance to access inspector profiles and tailor your preparation to their known priorities.

Deanna’s Unique Insights: Beyond the Obvious

In addition to the patterns above, Deanna sees a few emerging trends you may not yet be thinking about:

- Cybersecurity: As equipment and systems become more networked, inspectors are starting to ask more questions about how you secure data against breaches or tampering.

- Supply‑chain vulnerabilities: The pandemic exposed weaknesses in global supply chains. Expect more questions about contingency plans and how you qualify alternative suppliers.

- Analytics and dashboards: Inspectors appreciate seeing real‑time monitoring tools, provided they’re validated and you can explain how they work.

Her advice: “Don’t just prepare for the last inspection. Prepare for the next one.” In other words, anticipate where expectations are headed and build systems that are flexible enough to evolve.

What Compliance Teams Should Do Now

Being ready for an audit is about more than a tidy SOP binder. Here are some steps Deanna recommends you take today:

- Know your site’s inspection history: Review past 483s, warning letters, and inspector profiles.

- Have live access to regulatory trends: Stay informed on what the FDA is currently flagging across the industry.

- Practice your responses: Train staff to confidently answer questions and explain records.

- Keep CAPAs tight and tracked: Nothing undermines credibility like unresolved or ineffective CAPAs.

- Benchmark your peers: See where others in your sector are being cited to spot your own blind spots.

FDA Audit Readiness Checklist

To make it actionable, here’s a quick checklist to guide your preparation:

- Review prior inspection reports and closure letters

- Map and rank site risks by severity

- Validate electronic systems for compliance and integrity

- Update supplier qualification files

- Train teams on responding clearly and accurately

- Audit CAPA logs for overdue or weak actions

- Trend EM and deviation data proactively

- Profile your upcoming inspector’s known priorities

Final Thoughts

FDA audits are a fact of life in this industry. But they don’t have to be a fire drill.

By learning from experts like Deanna Bousalis and adopting smarter tools, better analytics, and systematic preparation, you can turn an audit from a scramble into an opportunity to demonstrate your team’s professionalism and commitment to quality.

The reality is simple: every inspection tells a story. It’s up to you whether yours is about a company that reacts only when pushed, or one that stays ahead of the curve and sets the bar.