Why a True Electronic Components Supplier Is More Than “Just a Seller

If you work in electronics procurement, you’ve likely lived this scene: a late-night email announces that a critical microcontroller has gone end-of-life just weeks before your next production run. Timelines wobble, customers wait, and downtime costs start to tick upward—minute by minute, hour by hour. In that moment, the distinction between a transactional box-mover and a true partner feels stark. To stabilize your operation with a dependable electronic components supplier, click here(electronic components supplier).

What changed? Supply chains are tighter, lifecycles move faster, and compliance expectations are higher. “We can ship it” is no longer sufficient when teams are judged on on-time delivery, predictable cost, and quality claims. Organizations need suppliers who anticipate risk, surface options early, and stand behind every lot they ship. The rest of this article explains what that looks like in practice—and how to evaluate it without relying on marketing language.

What Makes an Electronic Components Supplier a True Partner

So what separates a box-moving vendor from a genuine partner? It isn’t louder promises—it’s operational proof in the places where risk actually shows up.

- Proactive lifecycle management — Early visibility into PCNs, LTBs, and EOL events, paired with practical alternatives and impact assessments. The aim is to prevent last-minute redesigns and line stops before they become calendar events.

- Authenticity and warranty — Documented quality processes (e.g., ISO-aligned QMS), batch traceability, Certificates of Conformance on request, and incoming inspection when appropriate—so DPPM issues become exceptions rather than patterns.

- Hard-to-find sourcing — Access to a vetted, global network and the ability to recommend cross-parts, compare electrical/functional fit, and support AVL updates—turning “no stock” dead ends into viable paths forward.

- Scalable supply — Support that begins at prototype (small batches, flexible MOQs, mixed orders) and scales to volume with consistent PNs, realistic lead-time commitments, and region-appropriate logistics.

A partner supplier doesn’t replace engineering or procurement; it amplifies both by surfacing timely options and sharing the operational load. For manufacturers that want more than shipments—suppliers who provide lifecycle insight, authenticity, sourcing support, and scalability—the difference is clear. Working with a trusted electronic components supplier that delivers on these capabilities helps procurement teams turn uncertainty into control. click here(electronic components supplier).

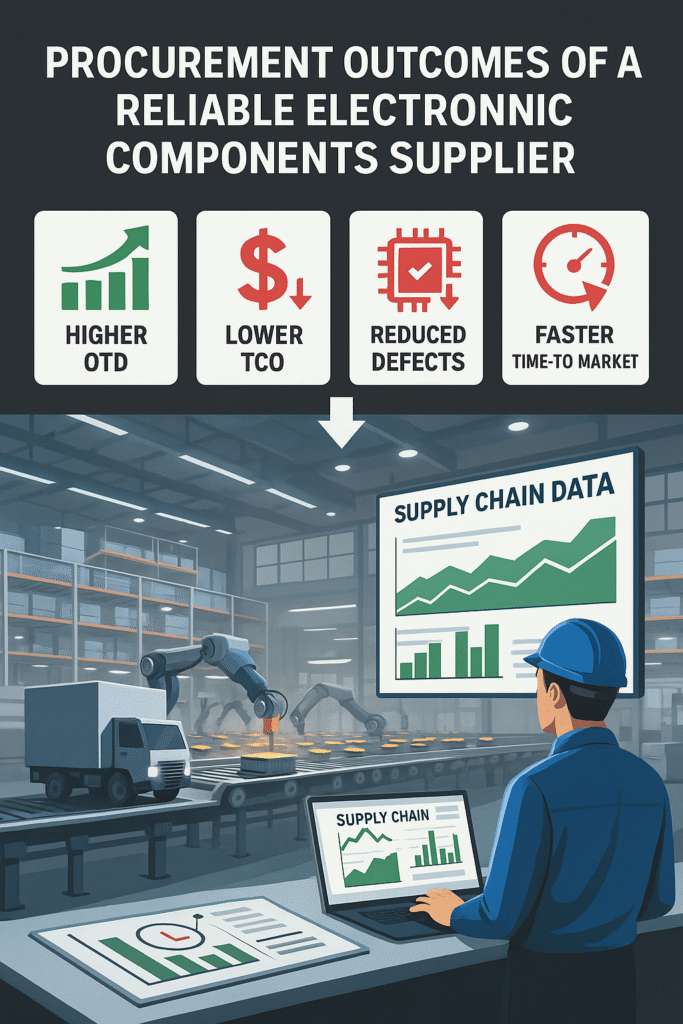

Outcomes That Matter to Procurement

Procurement leaders don’t evaluate vendors by adjectives; they evaluate outcomes. A partner-grade supplier should move the needle on the metrics that govern your work:

- Higher on-time delivery (OTD)

Predictable schedules, transparent inventory positions, and candid commit dates keep builds on track and rescheduling costs contained. - Lower total cost of ownership (TCO)

Unit price is only one line in the spreadsheet. A partner helps reduce expedite fees, freight surprises, rework, and—most expensive of all—line downtime. - Reduced defect rates (DPPM)

Traceable lots, quality gates, and warranty-backed accountability lower the frequency and severity of quality claims and the hidden cost of investigative churn. - Faster time-to-market

Smooth handoffs from sample → pilot → mass production compress the NPI cycle, letting you capture demand windows without risking component churn mid-launch.

Each outcome ties directly to margins, customer commitments, and brand reputation. In short: outcomes are the proof that “partner” is more than a label.

Mini Case #1: Hard-to-Find Parts, No Line Stop

A European automotive supplier received an EOL notice for a key microcontroller just before a production ramp. Regular distributors confirmed the shortage and offered condolences. A partner-level supplier approached the problem differently: within 48 hours it proposed cross-part options, documented functional fit against the AVL, flagged layout considerations, and arranged a small pilot lot so boards could be built.

The customer validated the alternative within a week and avoided a projected multi-week line stop. The “win” wasn’t only continuity—it was process. Procurement left with a repeatable playbook for lifecycle shocks; engineering gained a faster path to evaluate equivalents. Both teams reduced risk the next time a PCN hit their inbox.

Mini Case #2: From Prototype to Production, Seamlessly

A fast-growing IoT startup began with runs of only a few hundred boards. Traditional distributors either refused the business or layered fees that made iteration expensive. Working with a flexible partner supplier, the team secured small-batch deliveries of RF modules during design—without punitive MOQs or opaque lead times.

Six months later, as production scaled to tens of thousands of units per quarter, the same supplier stayed in lockstep: consistent component families, phased delivery schedules, and on-time performance that kept customer promises intact. Qualification remained straightforward, risk stayed controlled, and the launch timeline accelerated instead of slipping. The takeaway wasn’t just price competitiveness—it was the ability to scale without drama.

Checklist & Red Flags

When the marketing pages all sound similar, use a simple, verifiable filter.

What to Look For

- Certifications & traceability — A documented QMS (e.g., ISO 9001) and COC availability; clarity on how non-conformances are handled.

- Inventory transparency — Realistic commits, clear stock positions, and honest lead-time expectations (including when things slip).

- Alternative sourcing support — Cross-part guidance, AVL evidence, and lifecycle alerts with recommended next steps.

- Flexible terms — Ability to support small batches, mixed orders, and phased deliveries during NPI without punitive policies.

- Logistics & coverage — Multi-region options and relationships with established manufacturers, so supply isn’t dependent on a single lane.

Red Flags to Avoid

- Price-only pitches with no documentation behind quality or provenance.

- Blanket NCNR on everything, regardless of project stage or context.

- Vague “global network” claims with no specifics or references.

- Resistance to providing COC or discussing inspection/traceability.

- No examples of measurable outcomes—only generic promises.

Practical Steps to Test a Partner Supplier

Identifying the right supplier is only half the challenge—testing them in practice is where confidence is built. Start small and measure:

- Run a pilot order for critical but non-urgent parts. Track OTD, communication responsiveness, and any gaps between quoted and actual lead times.

- Request lifecycle insight on one active BOM. Evaluate how quickly the supplier flags PCNs or EOL risk and what alternative paths they provide.

- Assess flexibility with a mixed-quantity request. Note how MOQs, phasing, and terms are handled—and whether solutions are proposed proactively.

These steps turn a checklist into lived experience. Instead of relying on sales language, you’ll see how the supplier performs under your project’s constraints before scaling the relationship.

Why This Approach Works (Tying It Together)

The through-line across definitions, outcomes, cases, and checklists is simple: reduce the cost of uncertainty. Components age; demand shifts; logistics snags happen. Partner-grade suppliers don’t erase volatility—they buffer it with earlier signals, better options, and accountable execution. That’s what transforms “we ship parts” into “we protect schedules, budgets, and reputations.”

Conclusion: Beyond Distribution

The electronics supply chain is too critical to entrust to vendors who only move boxes. Modern procurement teams need suppliers who anticipate lifecycle turns, stand behind authenticity, adapt to small-batch starts, and scale without friction. A true partner supplier does more than cut purchase price—it prevents downtime, accelerates time-to-market, and strengthens long-term competitiveness.

In an environment where hours of delay can ripple into missed shipments and lost orders, choosing the right supplier isn’t a convenience. It’s a strategic decision that defines how resilient—and how competitive—your manufacturing operation can be.