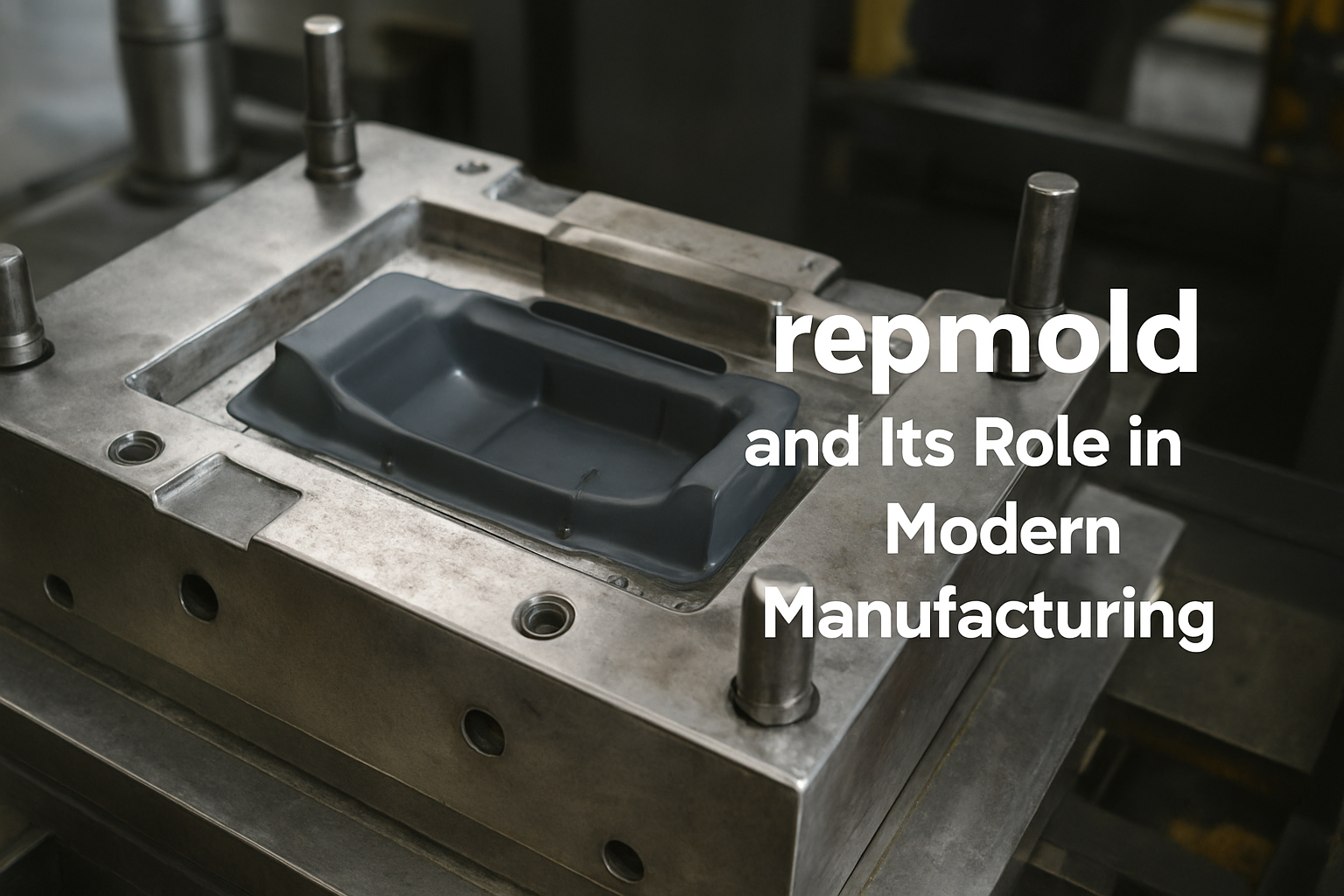

Repmold is a specialized tool used in the process of molding. It serves as the form or cavity into which materials like plastic, metal, or composite substances are shaped. Once the material is pressed, injected, or cast into the repmold, it takes the mold’s shape after cooling or setting. This process is vital in manufacturing because it allows identical parts to be created quickly and efficiently.

The name repmold is connected to its purpose: repeating a mold to ensure mass production of consistent products. Without repmold, industries like automotive, packaging, or electronics would struggle to produce items at a large scale with the same quality.

The History of repmold

The idea of molding dates back thousands of years. Ancient civilizations used stone and clay molds to create weapons, jewelry, and pottery. However, the modern repmold evolved during the Industrial Revolution. Machines capable of melting and shaping metal or plastic required more precise molds.

By the mid-20th century, repmold technology advanced with the invention of injection molding. Factories could now mass-produce parts with extreme accuracy. Over time, digital tools like Computer-Aided Design (CAD) made it easier to design and refine repmold products. As industries demanded faster and cleaner methods, the repmold became a cornerstone of manufacturing.

Common Uses

Repmold is not limited to one sector. It is widely used across industries, including:

Automotive parts: Engines, dashboards, and small plastic clips are all made using repmold.

Packaging: Containers, bottles, and caps rely on precise repmold shaping.

Medical tools: Syringes, implants, and protective equipment require clean, exact molds.

Electronics: Cases for phones, laptops, and other devices are designed with repmold.

These applications show that repmold is essential for producing the items people use every day. It combines speed, accuracy, and efficiency to meet the high demands of modern society.

Materials Used to Make repmold

The construction of a repmold depends on its purpose. Common materials include:

Steel: Known for its strength and durability, steel is used for molds that must withstand thousands of cycles.

Aluminum: Lighter and easier to shape, aluminum molds are used for shorter runs or prototypes.

Copper alloys: These materials conduct heat well, which reduces cooling time and increases production speed.

In some cases, coatings are added to repmold materials to prevent wear or make them resistant to corrosion. Choosing the right material ensures that the mold performs efficiently and lasts as long as possible.

Why repmold Matters in Daily Life

Even though most people never see repmold directly, they benefit from it every day. From the toothbrush used in the morning to the car driven to school or work, repmold shapes countless products. Because it guarantees consistency, customers can trust that items like medicine bottles or electronic parts are safe and reliable.

Additionally, repmold keeps production costs low. Mass manufacturing reduces the price of goods, making them more affordable for everyone. Without repmold, everyday products would either cost much more or lack quality control.

Environmental Benefits

Repmold also plays a role in sustainability. Although molding involves resources, efficient designs help reduce waste. For example, repmold techniques minimize excess material, cutting down on scraps. Moreover, recycling is easier because molds can be designed to use eco-friendly or biodegradable materials.

Energy-efficient repmold systems further reduce carbon footprints. By cooling faster and using fewer raw resources, factories can lower emissions. As industries shift toward green production, repmold will continue to support eco-conscious goals.

Innovations in repmld Technology

Technology has revolutionized repmold in several ways. Some of the most notable innovations include:

3D printing of molds: Instead of carving molds from metal blocks, 3D printers can create repmold prototypes faster.

Smart molds: Sensors embedded in repmold monitor temperature and pressure, ensuring accurate results.

Simulation software: Before production begins, engineers use programs to test designs virtually. This reduces errors and saves time.

These advances allow industries to push the limits of design while maintaining high efficiency. In the future, even more automation and artificial intelligence may transform how repmold is created and used.

Challenges with repmold

Despite its benefits, it faces challenges. Manufacturing molds is often expensive. Precision tools and skilled labor are required, which increases costs. Additionally, mistakes in mold design can lead to entire production lines failing.

Another problem is wear and tear. A repmold may produce thousands of items, but eventually, it weakens. Maintenance and replacement are necessary, adding to overall expenses. Finally, while repmold is moving toward eco-friendliness, some processes still rely on energy-heavy methods that impact the environment.

Cultural and Economic Role

It might not appear in cultural symbols, yet its role in society is undeniable. Economies depend on mass production to provide affordable goods. Without repmod, industries like healthcare, automotive, and electronics would not function smoothly.

From an economic perspective, repmod creates jobs. Engineers, technicians, and factory workers all rely on molding industries. Training programs worldwide prepare young people for careers in repmld design and production. Its silent but steady influence on economies proves its cultural and social importance.

Future

The future of repmod looks innovative and sustainable. Scientists are exploring biodegradable materials that can be molded safely. AI-driven design tools will improve accuracy and reduce errors. Factories may even adopt robotic systems to maintain and clean repmld automatically.

Furthermore, repmod will continue to adapt to global needs. As demand for renewable energy devices, medical equipment, and high-tech gadgets grows, the need for repmld will expand. It will remain at the heart of mass production, ensuring that technology and sustainability work hand in hand.